Why Screw Foundation

Sustainable, durable, revolutionary

Our company philosophy

Sustainability

While the issue of sustainability used to be far from a hot topic, here at EuroMbao and Partner Krinner we have always made an effort to manufacture responsible and environmentally-friendly products. Making progress with the smallest possible ecological footprint is our company credo.

We began working on alternative solutions for the construction industry early on to help tackle soil sealing and crop damage. The result: a foundation that can be removed and that barely damages the landscape and soil structure.

The affordable foundation solution for challenging applications has not only had an ecological impact on the market but it has also changed it in the long-term as it offers an eco-friendly alternative to traditional concrete foundations in many areas of application.

Durability

Our Partner is a down-to-earth, healthy company that has worked hard to secure its place as a leading provider of ground screws. High quality standards, motivated employees and a large network of sales partners are the three solid pillars of our constant progress.

As a reliable and professional business partner, we continuously work on optimising our range of products, accessories and services and we guarantee a future-oriented portfolio with secure sales and marketing prospects.

Our Partner remains true to its vision of developing innovative foundation products and having a lasting impact on the market.

Revolutionary

With our ground screws, we have revolutionized foundation construction in many areas of application and made it much more efficient. Each ground screw contains a bit of the KRINNER revolution.

This means that our customers and partners can be sure that they are getting the best product on the market and that they are kept up to date with all of our latest products.

Foundation construction with KRINNER ground screws

Do you have a construction project and place particular importance on eco-friendliness, safety and efficiency? Then you should take these aspects into consideration when planning your foundations. Foundation construction with KRINNER ground screws is an innovative and sustainable alternative to a classic concrete foundation.

A tried-and-tested principle

Ground screws are based on the principle of pile foundations – one of the oldest and most reliable types of foundation. It consists of a galvanised steel pipe with a welded on thread which is designed to support horizontal and vertical loads in the ground and is installed with the help of a ground screw driver. This type of foundation is capable of carrying the same loads as concrete foundations. Using this type of foundation also rids you of the need to displace any earth when building.

A real all-rounder: grounds screws can be used as point foundations in surface foundations, as well as in economic deep foundations. But they can also be used when a foundation needs to be built in challenging situations. Regardless of whether you’re dealing with a construction project on steep slopes, in a small and difficult to access construction site or a project that is time-sensitive, KRINNER ground screws are an economical answer to almost any building requirement.

Areas of application:

Residential buildings and extensions

Container construction and temporary structures

Street signs

Railway infrastructure

Timber construction and landscaping

Home improvement and DIY projects

The advantages of KRINNER systems

With a KRINNER ground screw-based foundation, there are many advantages in comparison to a conventional concrete foundation that are sure to win you over. Our products have been designed to be extremely sustainable and they ensure a high level of efficiency and safety when it comes to installing your foundation.

Eco-friendly

No soil sealing

Barely any crop damage

Return to a green space

Recyclable and reusable

Efficient

Makes it possible to access hard to reach construction sites

No need to move earth

Quick installation

Immediately loadable

Simple deep foundation construction

Safe

A method that has been used for centuries

High load-bearing capacity

Suitable screw driving and testing equipment

Highest quality standards

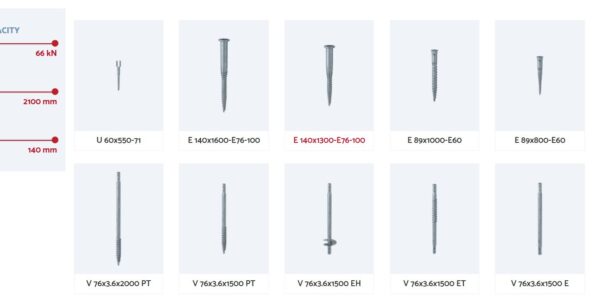

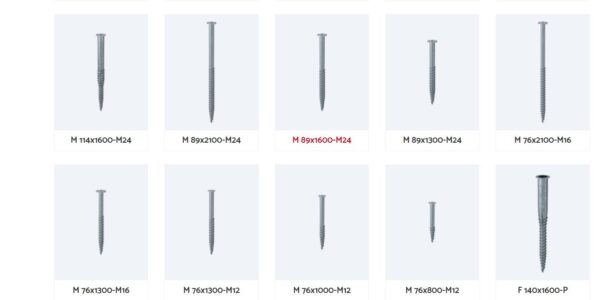

With our wide range of standard ground screws, here at EuroMbao-KRINNER we have the perfect solution for any conceivable application. What’s more, we can even tailor-make special ground screws for individual projects. As part of our KRINNER-EuroMbao services, we guarantee an on-time and complete delivery directly to the construction site.

Project process for a foundation construction with ground screws

Building a foundation with ground screws looks easy, and it is if you follow the individual steps. The project process for a foundation construction with ground screws always follows a similar pattern and is split into multiple process steps.

1. Subsoil evaluation

Before any construction project can start, a geological subsoil survey must be performed by a geotechnical engineer. This step must always be performed regardless of the type of foundation. The so-called “soil survey” provides information about the composition of the soil and can tell you whether it is a suitable subsoil or not. This information is obtained through boring and probing. Alongside the evaluation of the load-bearing capacity of the soil, the layer structure is also analysed and the groundwater behaviour evaluated. With a foundation construction with ground screws it is also necessary to investigate the aggressiveness of the soil in order to obtain a corrosion evaluation and therefore estimate how long the product can remain in the soil for without getting damaged. Finally, you need to check to see if the foundation will have an impact on any neighbouring buildings.

Fundamental planning

2. Foundation planning

With the geological survey, the load data from the object planning and the system structural analysis, you can now start the static planning of the foundation. It is important that you get the construction method approved in advance by the highest building authority in your region as this must be done on a case-by-case basis when using our ground screws (in Germany). The suitable ground screw type is determined and the number of ground screws needed is decided upon during the planning.

3. Load-bearing capacity test

The load-bearing capacity tests are used to check and confirm the estimates from the static planning with regards to the structural design in practice. They are also used to determine the installation parameters such as the minimum torque, for example. The load bearing tests are done using a test apparatus with a load cell and a tension-compression fatigue test in the direction of the load application, so vertical and/or horizontal, is also performed. Important: Before the load-bearing capacity test begins, approvals from the bomb disposal team and plans for underground cables must be obtained where needed.

4. Installation and documentation

After the report for the load-bearing capacity tests has been compiled, it must be checked, modified and approved by a structural engineer and only then the installation process can begin. First of all, the ground screw positions must be determined and then the ground screws can be installed by an expert machine operator with an electric or hydraulic KRINNER ground screw driver. During this process, the torque at the ground screw positions must be recorded and documented as evidence. The installation times are very short and loads can be placed on the foundations immediately after their installation. This means that the total construction time can be greatly reduced.

Easy dismantling

5. Dismantling the construction

If a construction project is only intended to be used for a short period of time, then dismantling it should also be made easy. The KRINNER ground screws can be easily unscrewed and removed. It is also possible to use the ground screws again. However, before reusing them, you need to check that the product hasn’t been damaged. A ground screw can only be used again if not damaged. If it is damaged it can be recycled and therefore disposed of in a sustainable way. After the ground screws have been unscrewed and removed the building site can be returned to its original state.

When compared to the process for installing a concrete foundation, the process steps for installing a ground screw foundation are similar but the whole installation process is significantly more efficient and faster. This means that the ground screws are definitely a viable alternative to more traditional foundation solutions.

KRINNER ground screw drivers

We have the right screw-driving technology and know-how for all our KRINNER ground screws. We have a range of screw drivers that we designed and manufactured ourselves to meet the diverse range of possible applications. You can choose from electric manual screw driving tools, hydraulic excavator add-ons and self-driving caterpillars. Each machine fulfils different requirements and has specific advantages. However, all KRINNER machines have one thing in common: they are very light and simple to operate, but they are extremely powerful.

KRE 17 – The affordable entry-level model

With the KRE 17, you can quickly and efficiently install professional foundatio

n solutions by hand. All KRINNER ground screws with a pipe diameter of 140 mm and a length of 1600 mm can be driven in with these machines.

Performance characteristics:

- 230 volt

- Approx. 3,000 Nm torque

- Compatible with all Krinner screw driving attachments

KRE 20 – The powerful step up

In principle, the KRE 20 covers the same areas of application as the KRE 17, but it is more powerful with more torque.

Performance characteristics:

- 230 volt

- Approx. 3,500 Nm torque

- Compatible with all Krinner screw driving attachments

KRB 250 – The powerful solution

With the KRB 250 you can even drive very large foundation types into hard layers of the ground. It can even cope with rocky substrates with just prepared sounding drillings and nothing else.

Performance characteristics:

- Base vehicle required: Excavator weighing from 8 t

- Approx. 20,000 Nm torque

- Hydraulic driver add-on

- Automatic orientation in the X-axis

KRL – The perfect combination of precision and strength

With the KRL, you can install ground screws extremely precisely and exactly with corresponding power thanks to the drill guide. This way all KRINNER ground screws can be installed for all types of application, but in particular the large V-series ground screws.

Performance characteristics:

- Approx. 15,000 Nm torque

- Quick-change device

- For projects with large foundations (diameters up to 140 mm; wall thickness up to 6.3 mm)

KRD 30 – Lightweight but powerful

Just like the KRL, the KRD 30 provides an outstanding level of precision during installation thanks to its drill guide. In addition, due to its light and manoeuvrable design it can be used in particularly small and difficult to access construction sites. Adaptors for various different drilling tasks (down-the-hole-hammer, core drilling bit or augers) complete the performance profile.

Performance characteristics:

- Approx. 8,000 Nm torque

- 2.4 m drill lift

- Only 1.1 t transport weight

- Precisely-defined feed force

Our products

KRINNER ground screw identification key

How to use screw foundation

[video_popup url=“https://www.youtube.com/watch?v=2mO7Hh2KhkM“ text=““]

[video_popup url=“https://www.youtube.com/watch?v=ZKr7CPyfqYk“ text=““]

[video_popup url=“https://www.youtube.com/watch?v=LnnBWeBbmBc“ text=““]